Screen printing infuses your design into fabric with precision and durability, using a mesh-based process that applies each colour separately and dries the ink for a long-lasting finish. This method is not only cost-effective for bulk orders, but it also excels with complex, large-scale designs on a variety of fabrics, making it the ideal choice for vibrant, customised and durable apparel.

LOGO & ARTWORK

BRANDING

EXAMPLES OF OUR WORK

SCREEN PRINTING ARTWORK FILES

Submit your artwork in high-resolution vector files (AI, EPS, or PDF) for the best results. These formats ensure your logo or design’s finest detail and colour accuracy. Our team of experts will guide you through the preparation process and ensure your artwork aligns with your brand and colours.

FILE

Vector file format is required to ensure best production outcomes. Accepted file formats: PDF, EPS, SVG, Ai. Please include your style guide where available.

SIZE

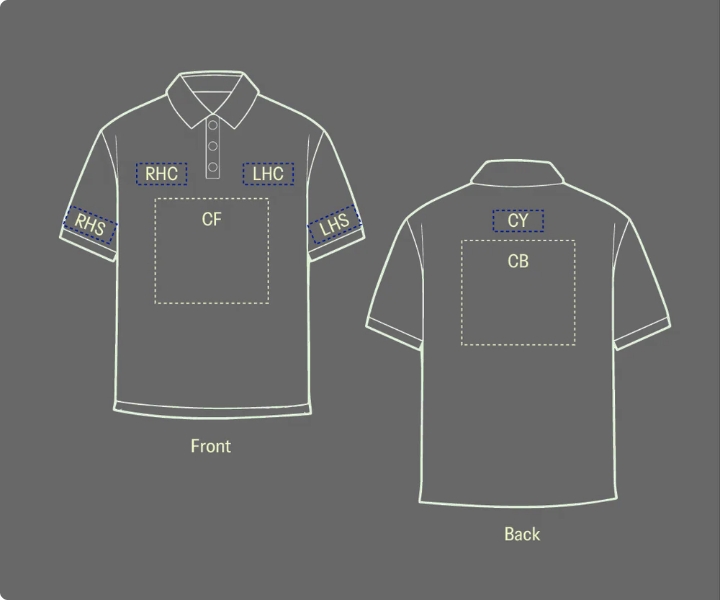

Once we have received your vector file, we can rescale to appropriate size. *Typical breast size for breast position is 100mm wide. This may vary depending on the specifics of your logo and garments in your order.

COLOUR

Vector files contain colour codes for us to reference in the production of your order. Pantone colour system is always preferred. Thread colours are matched to pantone by ‘best match’.

We are highly experienced graphic designers, and our in-house team understand how to make your uniform work for your organisation.

SCREEN PRINTING FAQS

10,000+

Satisfied businesses under our belt

Unlock Tailor-Made Updates

Discover the latest workwear trends and receive exclusive offers straight to your inbox.

By clicking Subscribe you’re confirming that you agree with our Terms and Conditions.